Self-cleaning of domestic wells from silt. Their structure, causes of clogging and methods of its elimination. Some tips for preventing siltation of water sources. Sludge removal from a well is a measure aimed at maintaining the productivity of a water source. As a result of siltation, its debit may decrease and even disappear. You will learn how to clean the well from silt with your own hands after reading this article.

Well device

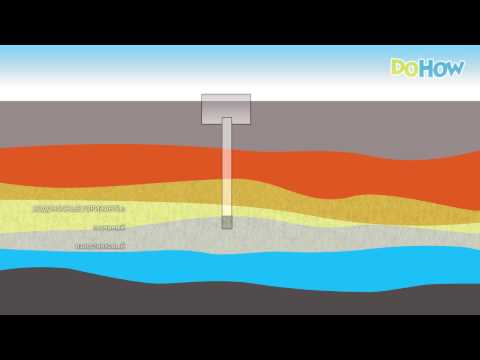

To understand the process of cleaning a silted well, one should have an idea of how it works. This will greatly simplify the work and improve its quality.

There are two types of wells depending on the design:

- With a barrel made of pipes of the same diameter;

- With a filter, the diameter of which is less than the size of the casing pipe.

Wells of the first type are simpler and more popular, since their design allows the pumping-out pump to be lowered to the bottom, preventing its operation from silting up the source. The trunks of structures are assembled from pipes of the same diameter, connecting them by welding, or screwing them onto each other using a thread. When a well of the first type is silted up, it can be easily cleaned up by gradually lowering the pump to the full depth of the source.

The well of the second type is equipped with a filter, which is permanently located in the aquifer of the soil. The filter is made of two perforated pipes of different cross-sections. There is a spiral wire between them. The layout of such a well does not allow the vibration pump to reach the bottom of the source. This is its disadvantage.

Reasons for well siltation

Quite often, the reason for the siltation of a home source is the insufficient consumption of its water. At the same time, clay particles gradually settle in the well, which, over time, reduce its flow rate. If you use it constantly, the risk of silting up is minimal. Sometimes it is useful to turn on the vibration pump for a long time with the sole purpose of pumping out the maximum amount of water that carries unnecessary impurities out of the well with it.

Other causes of siltation:

- An error in determining the drilling depth. If it does occur, water can enter the well from poorly saturated underground layers.

- Water supply by means of rotary pumps, which are suitable for pumping water from a depth of up to 10 m. Suspended matter below settles to the bottom of the well. A vibration pump can help in such a situation.

- The use of a filter, the lateral dimension of which is less than the borehole diameter. In this case, the pump can go down, even before reaching 20-30 cm of the top of the filter, which will eventually fill with deposits.

- Application for pumping out a vibration pump with an upper intake of liquid.

After determining the cause of the appearance of silt in the well, you can start cleaning it or know how to prevent clogging of your home water source in the future.

Well cleaning methods

Cleaning of silted wells with the help of special vehicles, kindly provided by many companies, is not affordable for everyone. In addition, for some reason, the access to the source may be limited. Below you can see some of the methods for independent use.

Using a bailer for cleaning a well

Despite the considerable laboriousness, this cleaning method is quite reliable. Even an idle well can be restored to its original state with a bailer, removing silt and small stones from it.

The design of the bailer is quite simple, so you can assemble it yourself. To do this, you need a pipe 50 mm in diameter and 60 cm in length, as well as a steel ball 40 mm in diameter. A bottom made of a thick-walled washer must be inserted into the lower end of the pipe. From above, it should be in the shape of a funnel. The washer bore must be adjusted to match the ball diameter. After that, the washer should be welded to the end of the pipe.

The upper part of the pipe must be equipped with a wire grid to hold the ball in the structure and a metal arc for attaching a steel cable or cord to it. The lattice and arc are fastened by welding. To increase the efficiency of the system, four steel tusks can be welded to the bottom of the pipe to loosen silt or sand.

In the process of making the bailer, there may be a problem with finding a ball with a diameter of 40 mm. There are three options to solve it:

- Buy a ball in the market;

- Order its production by a turner;

- Make it yourself.

Let us dwell on the last option in more detail. In the toy shop you can buy a ball of a suitable diameter made of PVC or rubber, and in a hunter's shop you can buy lead shot. Arriving home, the ball needs to be cut in half, and the shot should be mixed with waterproof glue and filled in the halves of the ball. When the glue is dry, the hemispheres must be glued with epoxy resin, and the seam must be sanded. Such a product will function properly and for a long time as a valve in the thief hole. Lead shot can be successfully replaced by steel balls from bearings.

Before you clean the well from silt, the thief must be tied to a long cable. After that, it should be lowered until it touches the bottom, then raised by half a meter and lowered again, but already abruptly. The ball, possessing potential energy, will free the lower hole, water with suspensions of silt and sand will rush into it. Then the ball will cover the hole. To fill the thief in half, you must repeat this operation 3-4 times. Then, without jerking, you need to lift it and pour the silted water out of it.

At one time, using a bailer, you can remove about 300 g of contaminants from the well without taking into account the amount of water. This is approximately 30 mm of the height of the silty layer. To facilitate the work will help a specially made to extract the gate device.

Using a pump to clean a well

This method is more progressive, its productivity is an order of magnitude higher than when cleaning with a bailer. In addition, significant physical exertion is absolutely not required here. The disadvantage of this method is the difficulty in determining the bottom of the source, but in this case such a problem does not matter much.

For cleaning, you can use the pump "Kid". From below on the tube of the device for the intake of liquid, it is required to put on a strong hose of suitable diameter and press it with a metal clamp. Since the mechanism is vibrating, an additional safety device must be provided in the hose attachment.

A polyvinyl chloride tube should be inserted into the cavity of the hose and a weight should be attached to its lower end. It will prevent the hose from floating when the pump is placed in the wellbore. All connections must be secured.

Then the pump, complete with nozzles, should be lowered into the well and turned on. Cleaning must be carried out until clean water comes out of the well.

It is possible that after completing the entire procedure, the pump piston will have to be replaced. But this should not be considered a problem, since such a spare part is attached to the pump when it is purchased.

Mechanized hole cleaning method

This is the most efficient way to remove sand or silt from a well. It provides for the use of 2 pumps working in one pair. The downhole apparatus is located at the bottom of the well. Its purpose is to lift up silt-polluted water. And with a pump operating nearby, water is pumped from a special reservoir under pressure into a well to stir up the sludge at the bottom of the source. Both pumps must be correctly selected depending on how deep the aquifer is located.

In practice, this process looks like this:

- It is necessary to install some kind of container near the well, for example, a 200 liter barrel. Its upper part must be equipped with a filtering device, which can be made from an old bucket by replacing its bottom with a mesh. The water supply hose from the pump must be fixed in the filter. Its second hose should be equipped with a load, for example, a piece of pipe, and lowered to the bottom of the well.

- The submersible pump must be installed inside the source so that it does not reach a silt level of 10 cm. To do this, the pump must first be immersed on the bottom of the source, and then raised to the required height and secured with a fastener.

- Start the submersible pump, filling the barrels with water to the top. After that, turn on the pump supplying water downward to loosen the sludge at the bottom of the source.

After installing and turning on the pumps, it remains only to observe how dirty water comes from the well. If there is too much suspended matter in it, then the supply hose should be slightly raised, as it can become clogged due to the heavy load on the submersible pump.

Periodically, the fluid supply hose must be wiggled and lowered slightly as the suspended solids are removed. In this way, cleaning the well from silt can be done in 2-3 hours. The duration of the process depends on the degree of pollution and the type of soil.

Well cleaning with compressed air

This method uses a well as a container of water. A pipe must be immersed in the source and air pumped by a compressor must be fed through it. This creates a foamy mixture in the shaft. Underground water creates pressure from below. Together with it, due to the difference in pressure, sludge rises, is absorbed by the pipe and is brought to the surface.

The method is quite effective. The task of the contractor is to control the level of the liquid so that it does not end in the well during the cleaning process.

Using this method, the source can be cleaned not only of silt. It is also suitable for removing sand and small stones. If the well is very contaminated, pressurized foamy fluid can be pumped through the hose from the fire engine. Cleaning will take only 10 minutes. However, this method is not cheap and also dangerous - the powerful pressure of foam can harm the system filter.

Well contamination prevention

It will not be possible to completely protect a home source from the accumulation of pollution in it, especially if it is not a deep artesian well. However, certain measures need to be taken:

- Initially, carry out a competent arrangement of the source and install high-quality equipment.

- Periodically monitor the purity of the water and regularly clean the well. It is easier than one-time removal of blockages, but immediately in a large volume.

- You need to use water regularly, often taking it from the depths to avoid stagnation. If the need for a summer cottage well is seasonal, then in winter it is advisable to visit the site once a month and a half and turn on the pumping of water.

How to clean a well - watch the video:

Before cleaning the well of silt, choose the method that is most suitable for your conditions. If it is sandy, its depth is shallow. The method of cleaning with a bailer or a conventional vibrating pump is suitable here. To remove blockages from an artesian well with a depth of 30 m and more, it is more convenient to use mechanized cleaning. When performing such work, you should always remember that clean water on the site is the main condition for a comfortable life. Good luck!