Wells clogging reasons. Source cleaning methods. Brief instructions on the mechanical removal of dirt and the use of chemicals to dissolve deposits. Well clean-up is the removal of sand, debris and salt deposits from the mine to restore the functioning of the source. The procedure is performed mechanically or using chemical reagents. How to clean the well with your own hands, you can find out in our article.

Reasons for well clogging

Sooner or later, every well begins to experience problems associated with water pollution. They are accompanied by a decrease in the level of liquid in the mine, the appearance of a large amount of sand and silt in the bucket. Water from the tap flows out in jerks, with a snort and air release. There are several reasons for well clogging.

Sanding

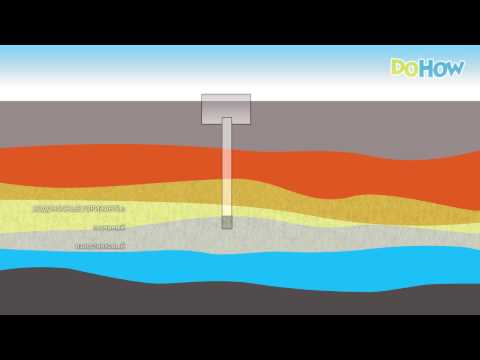

occurs at shallow springs with an aquifer in sand and gravel beds. If the well is built in accordance with all requirements, soil particles enter the mine in small quantities and cleaning will not be required soon. But when the technology of construction and arrangement of the trunk is violated, a lot of loose mass appears.

This can happen for the following reasons:

- Violation of the tightness of the head or caisson.

- The filter is incorrectly selected, for example, it has too large cells.

- Destruction of filter elements.

- Formation of gaps in the joints of the shaft elbows (the thread in the connection of neighboring elements is not twisted to the end, the welding of metal parts is poorly performed, damage to the plastic walls, etc.).

- The movement of the soil also leads to the ingress of soil into the well.

- Improper filter installation. If it has a smaller diameter than the casing, the pump pumps the water above it, leaving the bottom without circulation. As a result, a large amount of dirt accumulates at the bottom, which clogs the device.

- The threat of sanding the source or blocking the filter with a loose mass can be prevented by installing a sand separator, but its installation is carried out only at the construction stage of the source.

Silting up

appears in infrequently operated wells. The cause is particles of rust, sedimentary rocks, calcium deposits that collect at the bottom or form on the filter and clog it. Water stops flowing into the mine, its level drops. Drying out of the source can occur within 1-2 years. In frequently operated wells, this process takes decades.

Well cleaning methods

To restore the functioning of the well, one of three principles is used: pumping, flushing with a circulating stream and blowing with air under pressure.

Let's consider the most popular cleaning methods and recommendations for choosing procedures for your well:

- Pumping out dirt with a pump … For work, you need a vibrating pump with a lower intake. It pumps out water with small particles well and is able to lift even small pebbles to the surface. The method will not help in the case of serious siltation of the well and is not used for cleaning mines with a depth of more than 10 m.

- Washing the mine with a motor pump … The method consists in supplying liquid to the bottom of the well with a high-capacity pump under high pressure. The strong stream lifts sand and other small debris and carries them out through the throat. For this purpose, powerful fire engine pumps can be used, which clean the source in 10 minutes. The procedure will require a large amount of water, therefore it is recommended to reuse it. However, the motor pump can damage the filter or barrel, so this method should be used carefully and only in case of heavy dirt.

- Well flushing with two pumps … This technique is used in mines with a depth of at least 50 m. At such a depth, the power of one apparatus for cleaning a well is not enough: the vibration pump will not raise water to the surface, and when using an external motor pump, the dirt will settle before it reaches the top of the shaft.

- Application of special devices … The use of a wellbore thief is considered the most common and effective method of well resuscitation, despite its laboriousness. With its help, you can restore the original state of the source, remove sand and small stones from it. The bailer is a cylindrical tool whose diameter is less than the diameter of the casing. A valve is made in the body through which dirt enters the projectile, after which it rises to the surface together with the tool.

- Well cleaning with water hammer … This method is used to rid the filter and the soil around it from silt deposits. The need for a water hammer appears when other procedures have not led to the desired result. To create pressure, a heavy object is thrown into the well or a large amount of water is dropped at the same time. A sharp blow knocks dirt off the filter and walls, and then is pumped out.

- Cleaning with a gas-air mixture (bubbling) … It is used if the use of pumps has not been successful. For the procedure, you will need an air compressor and a motor pump. The air blows away dirt from the bottom and walls, and the motor pump removes the dirty liquid outside. The bubbling can last for several days or weeks if the source is very heavily clogged. But this method has an undoubted advantage over water hammer or the use of a thief - it is not capable of damaging the structure.

- Cleaning with a lift-airlift … The method consists in supplying air under high pressure (at least 15 atmospheres) into the well, to its bottom. During the cleaning of the well with the compressor, the air stream blows the liquid mud out of the well. However, it works if there is little water in the well.

- Use of chemical reagents … The method is used if it is necessary to remove deposits on the filter and on the walls of the barrel. For cleaning, it is recommended to use food reagents that are used in cooking, but in difficult situations, the action of aggressive chemicals is allowed.

Popular well cleaners are shown in the table:

| Chemical reagent | Application |

| Sorbic, citric and ascorbic acid | Universal agent for all types of deposits, used for minor well clogging |

| Xanthan gum and sodium benzoate | A multipurpose agent for various deposits, used in case of minor well clogging |

| Sodium dithionate | Has strong reducing properties, dissolves ferrous compounds |

| Technical hydrochloric acid | Dissolves ferrous deposits |

| Sodium tripolyphosphate | Dissolves most deposits |

| Orthophosphoric acid | Used in case of slight filter contamination, dissolves rust and calcium deposits |

| Hydrochloric acid | Used when the filter is heavily soiled |

Determining the reason for the decrease in debit is not easy, there are usually several of them. Therefore, different methods are used to restore the source:

- The appearance of small particles in the bucket means that the process is at an initial stage and the source is not silted up yet. In this case, start the procedure for cleaning the well from sand by pumping it with a vibrating pump. If no positive results are found, flush. Also start work with it if the source is almost dry.

- If you find a lot of sand, use a bailer. The tool is not used if the casing is plastic - the pressure created when the tool falls can break the wall.

- For cleaning of mines made of polymer products, only bubbling is allowed.

- If there is no water at all, and there is only sand in the well, use the water hammer technology. It will restore the water supply if the liquid has not gone to another level. Renting special equipment for this method is expensive, but even more expensive is the construction of a new mine.

How to clean a well

When working with wells, carry out all operations carefully so as not to harm the source even more. Below are brief instructions for cleaning mines in various ways, as well as the order of their use. Before using this or that method, it is necessary to prepare devices for working according to the chosen method and find a place where dirty water will pour out.

Vibration pumping

For work, you will need a vibrating pump capable of lifting fluid from the bottom of the well to the surface. The performance of the product is less than that of a circulation pump, but it is cheaper. Sand often destroys the foot valve, but it is inexpensive and easy to replace.

Even if the winding burns out during operation in extreme conditions, the financial damage will not be large compared to a centrifugal pump failure. Lower the pump into the well, leaving just a few centimeters between the suction port and the bottom. Run the outlet hose into a large container, otherwise the entire area will be covered in mud. Turn on the pump and pump out the water from the well. If there is a lot of it, after 10-15 mm, turn off the pump and let it cool down.

Pebbles 3-5 mm in size can get under the membrane and interfere with the operation of the product. You can get rid of them only after raising the device to the surface. The process of draining the well can take a long time due to the low power of the unit.

The water near the bottom can be muddied with additional simple devices. For example, using a metal pin with a welded nut at the bottom, which is attached to a thin long rope. Lower it into the hole so that it goes into the ground, and lift it up sharply, loosening the soil. The debris that appears will grab the pump and lift it out.

In some cases, the unit cannot be positioned close to the bottom. For example, if the filter is installed after the casing has been installed, it will narrow the well and the borehole at the bottom will be smaller than the pump. To clear the mine, do the following:

- Put a rubber hose on the pump water intake and fasten it carefully.

- Insert a metal or plastic tube into it.

- Tie a weight to the bottom of the hose to prevent it from floating.

- Lower the pump into the barrel until it touches the bottom of the tube, and then raise it a few centimeters.

- Pump out water in the same way as in the previous case.

Well flushing with two pumps

For work, buy or rent a vibration pump and a powerful motor pump.

Well cleaning is performed as follows:

- Place a container for dirty liquid next to the shaft.

- Install a motor pump nearby. Lower the outlet hose to the bottom of the well.

- Install a centrifugal pump in it so that the inlet is a few centimeters above the bottom.

- Turn on both pumps. The water flow from the surface will lift the dirt from the bottom, and the centrifugal pump will pump the dirty liquid out into the prepared tank.

Wiggle the hose regularly to prevent it from clogging. Cleaning can take several hours, depending on the degree of contamination.

Application of a motor pump for cleaning a well

For work, you need a product of high performance.

Perform the following operations:

- Install a large container near the source that exceeds the volume of the shaft.

- Fill it with water.

- Place a powerful pump next to it that will pump fluid from the container to the well under pressure. The hose must be long enough to lie on the bottom of the source.

- Cover the head with a special nozzle with a hose to drain the liquid into the reservoir.

- Turn on the pump and pump it into the shaft until it rises up the shaft and begins to flow into the container.

- Remember to remove the accumulated dirt from the tank.

Well cleaning with a bailer

Before starting work, stock up on materials for the manufacture of a lifting device, and also buy or make a thief.

Next, do the following:

- Assemble the instrument lifting tripod. To do this, you need logs with a diameter of 150-200 mm. The height of the structure should be 1-1.5 m more than the length of the device.

- Place a tripod over the well.

- Fasten to the top of the block.

- Pass a rope or chain through it and connect to a hoist, gate or other lifting device.

- Attach the bailer to the rope, lift up and make sure the tool is centered on the casing.

- Fix the tripod by digging in its legs at 0.6-0.7 m.

- Place the thief in the casing and release abruptly. The tool will enter the water and soil, and the valve will open and dirt will enter the projectile.

- Raise the attachment to a height of at least 1 m and release it again.

- Repeat the operation several times until the instrument is full.

- Raise the thief to the surface and remove the contents from the cavity of the projectile.

Repeat the procedure until the well is completely cleaned. After each lifting to the surface of the tool, the barrel will deepen only a few centimeters, so the process can take a very long time.

Sparging or cleaning with a gas-air mixture

Rent an air compressor and a motor pump for work.

Perform the following operations:

- Transport the air compressor and motor pump to the well.

- Install a large reservoir nearby to drain the dirty water.

- Insert a sprayer into the bottom of the well and connect a hose from the blower to it.

- Cover the shaft with a special nozzle that drains the liquid into the reservoir.

- Turn on the motor pump and compressor. Air bubbles form in the water, which will rise upward and remove debris outside.

After moving into the tank, the soil particles will settle to the bottom, and the water can be fed back into the well.

Well cleaning with water hammer

Make a special cylindrical device in the form of a large glass, the diameter of which is 0.5 cm less than the diameter of the barrel. Seal one side with a flat plug. Weld the eye on the opposite side and tie a rope to it.

The well cleaning procedure is as follows:

- Pour water into the well, raising the level by a meter.

- Lift the glass by the rope and release it. The projectile will fall into the water, which will hit the filter with some effort.

- Repeat the procedure for 2-3 hours.

- Remove the glass from the shaft and pump out all the water.

- Pump or flush the well several times.

- Measure the rate at which water flows into the well. If there is no result, repeat the operations with the glass.

Important! The water hammer can harm the source - damage the fine mesh filter or rupture the plastic casing.

Using hydrochloric acid to clean the well

When using the reagent, it is necessary to observe safety precautions: work in closed clothing, glasses and protective gloves. Also prepare a baking soda solution and clean water if you need to rinse the acid off your skin.

Do the following:

- Remove the pump from the shaft.

- Remove silt and sand with a thief.

- Measure the height of the water column.

- Prepare a 10% saline solution at the rate of 10-20 liters of reagent for 2-3 meters of a well with water.

- Place the pipe in the shaft so that it is in the middle of the filter and fix it in the center of the opening.

- Pour acid into the pipe, which will get to the filter without loss of concentration.

- Leave the well alone for a day.

- Water hammer: tie a cord to a plastic bottle, fill it with water and throw it into the mine several times. The water, together with the acid, should rise above the filter and dissolve the deposits on the wall.

- Postpone work for another day.

- Install a vibration pump in the well and drain it. All small particles will be removed from the mine together with the liquid.

- Replace the vibration pump with a centrifugal one and pump out all the water a few more times to completely remove the acid.

Preventive measures to prevent well contamination

To clean the wells as rarely as possible, follow our recommendations:

- After drilling, flush the wellbore with plenty of water until the turbidity disappears.

- Protect the source from contamination by making a head or installing a caisson. For temporary protection, the shaft can be sealed from above.

- Install the pump in the intake chamber in accordance with the requirements of the product manufacturer and taking into account the debit of the source.

- Do not use a vibrating pump to pump out water. Vibration causes small soil particles to penetrate into the trunk and siltation of the source. Such devices can be used for a short time, and for long-term operation, install a centrifugal pump in the source.

- The well must be used constantly. If it is used occasionally, pump out at least 100 liters of water at least once every 2 months.

How to clean a well - watch the video:

We have considered several simple and effective ways to clean water wells that you can do yourself. All of them have been repeatedly tested on various sources and have shown good results. But the result depends on the correct determination of the causes of pollution and the method of cleaning, so the process can take quite a long time.